Firstly, lets remind ourselves that hen’s would naturally place themselves into hierarchical flocks (hence ‘pecking order’), forage for food on the ground around them (they are omnivorous and eat insects, seeds, plants etc), lay eggs in a nest, flap their wings, ‘bathe’ in dust and dirt, and perch. So, let’s consider the various wording and labels on eggs in the supermarket, and where the eggs we are buying fit into the spectrum from as near to natural as possible through to the force farmed, mass produced versions.

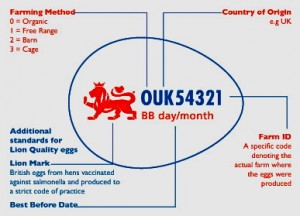

Under EU law the egg boxes must clearly declare how the hens are kept and each egg must be stamped with a code that further reveals the origin and method of feeding. This handy diagram from the

www.egginfo.co.uk website helps us decipher the code:

Lets look at this from left to right. According to the official

www.lioneggs.co.uk website:

‘The British Lion mark denotes eggs produced to a stringent Code of Practice incorporating the latest research and advice on Salmonella and eggs from scientists and vets. British Lion eggs account for more than 85% of UK egg production. The Lion Quality mark, which is a registered trademark, can only be used by subscribers to the British Egg Industry Council on eggs which have been produced in accordance with UK and EU law and the Lion Quality Code of Practice. The Lion Code of Practice is monitored by an independent agency in accordance with the EN 45011 standard. Farms and packing stations are regularly audited, including unannounced audits.’

But does the Red Lion stamped on the egg really mean anything of any actual importance? In 1988 when Edwina Curry announced in cavalier fashion that most of the country’s eggs were contaminated with salmonella, the sale of eggs plummeted and the poor outspoken dear was forced to resign. Let’s not let the personalities overshadow the facts. There was indeed a severe and dangerous problem with salmonella in eggs at the time and the Lion Quality Code of Practice and associated branding came in to attempt to rectify the loss of faith in the egg industry. This voluntary code is subscribed to by egg producers to show their hens are vaccinated against salmonella, and the eggs come with a ‘best before’ date for added assurance to us punters. Incidentally, many small scale, local, free range/organic places don’t vaccinate and claim, with some good sense, that their eggs are not from hens ever exposed to the deadly bacteria and not living in an environment where they are remotely likely to be exposed.

Ok, so that’s a plus point (ish) but what about the quality of the hen’s life and environment? Again I specifically ask this as these factors directly affect the egg and its nutritional value. Maybe like me you associate words like ‘free-range’ with open fields and no chemical enhancements, and make necessary assumptions, with no available further indications, of what ‘barn raised’, ‘colony raised’ and ‘organic’ actually mean. Incidentally, wording like ‘farm assured’ and ‘farm fresh’ mean bog all, so try to ignore these and focus in on the facts.

Just to the right of the stamped Red Lion is a number, each indicating the farming method:

0 – organic

1 – free-range

2 – barn

3 – caged

Let’s start with ‘caged’:

Clearly using the number ‘3’ looks less grim and off putting than using the word ‘caged’. This refers to battery cages, the original types which were banned only as recently as 2012 throughout the EU, and now replaced with so-called ‘enriched’ cages. Bizarrely it took years to get these first cages banned. With an average of four hens in each cage each hen had no more than a space the size of an A4 piece of paper to stand in and it could only just stand upright. The wire cages were stacked high upon each other with up to 100,000 hens reported in the largest factories. The cages pulled their feathers out and rubbed their skin raw and unable to expression any natural movement they attacked each other and many suffered broken bones and wings. Their beaks were trimmed to prevent them hurting or even cannibalising each other and they were left in artificial light with endless food so they just existed to lay eggs.

Enriched cages increase the size of the area the hen has to ‘live’ in (by about a postcard size per bird) and include perches (a small rail) and nesting boxes (well, one) – which means the hens will compete for access to them (remember the ‘pecking order’) – and the dominant birds will win. There’s a miniscule place to scratch their claws and generally express at least some of their natural instincts…well that’s the theory. However, don’t be fooled, the hens still cannot flap their wings and exercise or forage and still die young suffering from physical deterioration due to lack of freedom and space. There is still no daylight or fresh air and everything in their environment is controlled and artificial. De-beaking is still practised to protect the hens from hurting and cannibalising each other – yes they are that stressed and frustrated. The deafening noise and stench must be flooring in themselves. It’s still shameful intensive battery farming however you dress it. Most are passed their producing maximum within 18 months but they could ordinarily live to around 10 years old and produce eggs for a majority of their lives in different amounts.

THEN as a final degradation, now that the hen is considered knackered she is dipped in a weakly electrified vat of water to stun her and then hung upside down past an electric saw and slaughtered by decapitation…

Unless an ingredient list specifically states otherwise, the eggs contained in that sandwich you had for lunch, your children’s school dinners, any and all the prepared and processed foods you buy (which you shouldn’t be anyway, right?!?) will be from caged birds.

A word about yolk colour. Lots of us look for a nice plump golden yellow yolk and immediately think of healthy sunshine and free range hens. However, battery hens (and many others besides) are endlessly fed on grain and soya and some form of colourant is used to ensure the yolk you expect. A controversial synthetic additive called canthaxanthin is used often and where it is not a derivative of citrus peel is added. Obviously, the egg is as healthy as the food that helped form it, and this colour enhancement is of no nutritional value and is a con.

Finally, before we explore the alternatives, need I remind you to ask yourself where all the male chicks go? Useless to the egg laying industry do you think they are left to grow and used for some effective purpose or do you think they are disposed of? I looked into it and it was horrific. I’ll just tell you there was a conveyor belt and an electric mincer…it’s another black mark against humanity…

So what are our options…? In the next part we will look at ‘barn’, ‘free-range’, and ‘organic’.