Emulsifiers are the chemicals needed to create an emulsion. Therefore an emulsifier is an additive that keeps two substances, which would usually naturally separate from each other, mixed. In food this is usually oil and water. There are oil-in-water or water-in-oil versions used*. They are used in many food products and are vital for the texture, ‘conditioning’, stability, even taste and indeed structure of the product, many of which would look very unappealing and/or be more vulnerable to spoiling without the emulsifier. Products like bread would be uneven (large holes would be visible) have less size and a drier texture without emulsifiers. Ice cream, margarine and mayonnaise are other foods that are completely reliant on emulsifiers for their structure and texture.

*The science bit : Due to emulsifiers having two distinct parts to themselves, one that likes to be in oil and one that likes to be in water, when they are added to either version (oil-in-water or water-in-oil) they will coat the appropriate element and keep it from clumping together and consequently separating into their own layer within the product. So, in essence, in water-in-oil emulsions the emulsifier coats the water molecules to prevent them separating from the oil and vice versa in oil-in-water emulsions.

Nature has many perfect emulsions such as the usually quoted example of milk, where the fat molecules are perfectly suspended in the surrounding aqueous solution. These are usually some form of protein or phospholipids (enables oil-in-water emulsion – e.g. lecithin)

Commonly used emulsifiers are either purified natural versions or synthetic versions that are ‘copies’ of the natural and have very similar structures. The most usual are:

- Lecithin (E322)

- Mono/di glycerides of fatty acids (E471)

- Esters of monoglycerides of fatty acids (E472a-f)

Similarly to the emulsifiers these are used to create shape and texture and therefore make the food look and ‘feel’ good. Thickening and stabilizing additives work with the emulsifiers to do this, especially products that would be runny and/or unappealing without them, or would deteriorate during processing, transportation or cooking. The longevity and regularity of the structure of processed foods relies on these additives and indeed marks the key difference between what we make for ourselves, without these additives, and the foods we buy fully expecting long shelf-life, the ability to freeze and store etc.

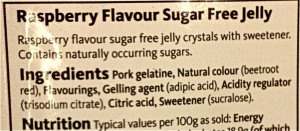

Without gelling agents many jams, jellies etc. would never set and remain stable (pectin added), fruit pie fillings would become runny and soak through the pastry long before reaching a consumer, and their use in soya protein products ensures that the soya product remains in tact even at high cooking temperatures.

Gelatine provided a key way to gel and set foodstuffs for many years but the animal source means that nowadays more often all-dietary issue inclusive alternative options are used, such as carrageenan. Gelatine is made by boiling animal carcasses (all bones and tissue) and the collagen turns to gelatin that can then be used as a powder or in sheets. Its effectiveness is also reduced by the presence of acid so pectin works better with high fruit content items such as jam.

The most commonly used are:

- Gum arabic (E414) from plant secretions (sap of the acacia tree)

- Guar gum (E412) extracted from guar beans

- Locust bean gum (E410) from the endosperm of seeds of the carob tree

- Xanthan gum (E415) from fermenting glucose or sugar

- Agars (406) extracted from specific red algae

- Carrageenan (E407) extracted from several types of, usually farmed, red seaweed (as used in the jelly crystals element of the trifle mix above*)

- Pectin (E440) extracted from fruit such as citrus peel or remainder pulp from pressed apples (as used in the Jaffa Cakes above)

- Starch (E1401-1451) isolated from many different sources such as potatoes, corn, wheat and cassava and from chemical modifications

- Carboxymethyl cellulose (466) made through a process of reacting cellulose with acids (a very common thickener as used in the jelly crystals and topping in the trifle mix above)

*The jelly crystals element of the trifle mix (shown above) also uses two chemicals disodium phosphate (a multi functional additive which can be used as an acidity regulator, stabilizer, emulsifier and/or to prevent coagulation) and potassium chloride (usually used as a salt substitute and/or and flavour enhancer).

Specific thickening agents added (whether gelling agents and/or stabilisers) are also used to provide bulk and fibre as their gum like properties are tasteless, odourless and have practically no calorific content.